Tách chất rắn-lỏng có tầm quan trọng không chỉ trong xử lý nước thải mà còn trong nhiều quy trình kỹ thuật khác. Để tăng hiệu quả của quá trình tách, người ta sử dụng chất trợ keo tụ polymers. Do đó, các hạt rất mịn có thể nhanh chóng được chuyển đổi thành các bông cặn và mạng lưới dạng vảy có khối lượng lớn và được phân tách tốt hơn khỏi pha lỏng. Các polymers là chất keo tụ hữu cơ phân tử cao với các mức độ liên kết ngang khác nhau. Chúng đã được phát triển đặc biệt để phân tách vật lý-hóa học của bùn lơ lửng. Các ứng dụng cho chất trợ keo tụ bao gồm các quá trình tách nước bùn và xử lý cặn lên men trong các nhà máy xử lý nước thải.

PHƯƠNG THỨC HOẠT ĐỘNG CỦA POLYMERS

Điều kiện tiên quyết cho quá trình keo tụ tối ưu của chất rắn là sự hấp phụ của các Polymers lên các hạt cần keo tụ. Các chất keo tụ có đặc tính phân ly thành các ion trong dung dịch nước, chúng còn được gọi là Polyelectrolytes. Liên kết giữa các phân tử chuỗi và các hạt lơ lửng dựa trên lực tĩnh điện và sự hình thành cầu hydro. Việc áp dụng các sản phẩm cần có sự tư vấn của một trong các kỹ thuật viên của MITSU để thiết kế chính xác tất cả các điều kiện bảo quản, sản xuất và định lượng dung dịch.

- Bùn thải

- Hỗn hợp bùn và Polymers

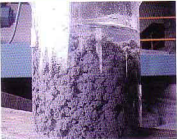

- Bùn trước khi vào hệ thống trục ép

Yếu tố quyết định để máy ép bùn làm việc hiệu quả,việc pha trộn bùn được quyết định bởi kinh nghiệm và kiến thức của các nhân viên vận hành của chúng tôi. Thông thường vấn đề bông bùn có những trường hợp sau:

- Không tạo bông hoặc bông quá nhỏ: Do hàm lượng chất rắn trong bùn quá ít hoặc Polymer sử dụng không đúng với tính chất bùn. Tỷ lệ giữa bùn và Polymer không phù hợp hoặc bùn chết => Bùn sẽ bị lọt qua trống quay ở “bước tách nước sơ bộ” => Không ép được bùn.

- Tạo được bông bùn nhưng Polymers quá nhiều: Polymer sẽ bám dính trên băng tải làm bít các lỗ thoát nước trong quá trình ép và rửa băng tải => Ép bùn không hiệu quả.